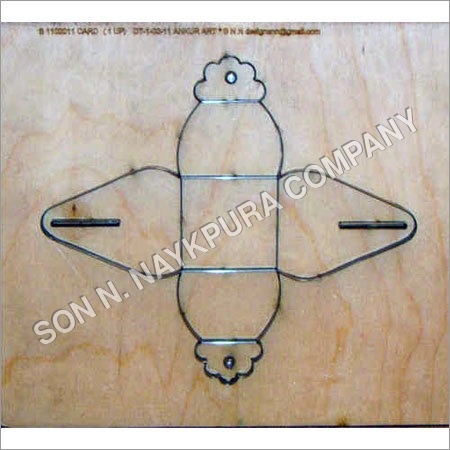

About Paper Cutting Dies

Having a definite quality management system, we are known as the noteworthy manufacturer of an enhanced quality Paper Cutting Dies. These products are widely used by various industries for cutting papers. Manufactured according to the industry standards, these products deliver high performance and durability. Our huge infrastructure facility is furnished with advanced machines and tools to manufacture these products. The expert professionals in our organization test every Paper Cutting Dies before delivery to ensure defect-free machines to our customers.

Precision Engineered for Diverse ApplicationsDesigned to operate with paper, cardboard, and various packaging materials, these flat dies maintain a cutting thickness of up to 5 mm. Precision CNC machining and EDM processes ensure a tolerance of 0.01 mm, delivering accurate shapes and clean finishes for each project requirement.

Custom Solutions for Unique RequirementsWe offer full customization of die sizes and shapescrafted according to your provided drawings or samples. Whether you need specialized dimensions or unique cutting profiles, our team adapts the dies to your workflow, supporting manual, semi-automatic, and automatic systems.

Long-Lasting, Efficient Cutting ToolsConstructed from tool steel or specified materials, our dies feature hardened steel punch dies and precision-ground heads. Finished with polishing or hard chrome coating, they maintain smooth, burr-free edges throughout their lifespan of up to 500,000 cuts. Every die is protected by secure packaging, ensuring intact delivery globally.

FAQs of Paper Cutting Dies:

Q: How are these paper cutting dies customized according to specific project needs?

A: You can provide your own drawings or physical samples, and our team will manufacture the dies to match your precise specifications, including shape, size, and special requirements. This ensures optimal fit and performance for your particular application.

Q: What materials can these dies process, and what is the maximum cutting thickness?

A: These dies are suitable for cutting paper, cardboard, and packaging materials with a thickness of up to 5 mm, maintaining clean and accurate edges even with heavy-duty use.

Q: When should I choose manual, semi-automatic, or automatic operation modes for these dies?

A: The choice of operation mode depends on your production scale and workflow. Manual mode suits low-volume or prototype jobs, semi-automatic is ideal for moderate batches, while automatic operation is recommended for high-volume, continuous production.

Q: Where are these dies typically used within the packaging and printing industry?

A: These paper cutting dies are commonly employed in facilities that process packaging materials, card stock, and paper productsranging from commercial print shops to large-scale packaging manufacturers.

Q: What is the lifespan of these cutting dies, and what factors contribute to their durability?

A: Each die is engineered for up to 500,000 cuts, thanks to the use of high-quality tool steel, hardened alloy cores, and advanced surface treatments like polishing or hard chrome coating, resulting in reduced wear and consistent performance.

Q: How does the production process ensure the accuracy and quality of each die?

A: Our manufacturing process utilizes advanced CNC machining and EDM techniques, along with precision-ground and hardened components. This results in a finished product with tight tolerances (0.01 mm) and smooth, burr-free cutting edges.

Q: What are the main benefits of using a customized flat die for cutting paper and packaging materials?

A: Customized flat dies deliver highly accurate and repeatable cuts, improve production efficiency, minimize material waste, and extend operational life, ultimately offering reliable output for specialized packaging and paper applications.