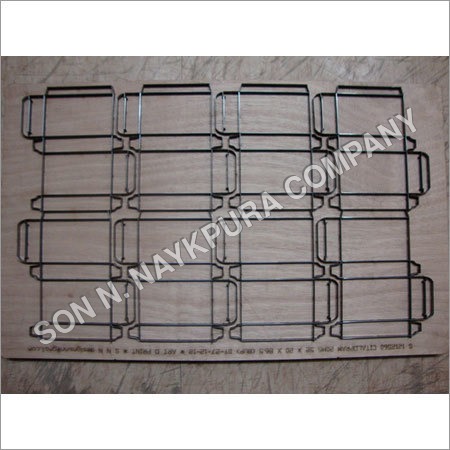

About Duplex Box Cutting Dies

As per the variegated requirements of our clients, we are providing a wide array of Duplex Box Cutting Dies. The offered dies are extensively used in heavy engineering industries. These products are manufactured under the direction of skilled professionals using optimum quality materials and sophisticated techniques. These are widely known in the market for their hassle free performance. Our customers can avail these Duplex Box Cutting Dies at reasonable price from us.

Precision Engineering for Consistent ResultsEach Duplex Box Cutting Die is engineered using precision CNC, EDM, and grinding processes, ensuring a tight tolerance of 0.01 mm. The combination of hardened steel die heads, wear-resistant punch dies, and high-strength steel bases delivers flawless performance, making these dies indispensable in demanding packaging operations.

Optimized for High-Volume ProductionWith a life span of over 100,000 cycles, Duplex Box Cutting Dies are tailored for manufacturers with large-scale production needs. Their robust construction and heat-treated surfaces guarantee consistent, high-quality cuts, even under intense usage, supporting efficient and reliable packaging workflows.

Customizable and Easy to MaintainThe dies are designed for easy dismantling and cleaning, reducing downtime and ensuring smooth operation. Customization options allow adaptation to any duplex box specification, enhancing flexibility and productivity for diverse packaging requirements.

FAQs of Duplex Box Cutting Dies:

Q: How can Duplex Box Cutting Dies be maintained effectively for optimal performance?

A: These cutting dies are designed for easy dismantling and cleaning, which simplifies routine maintenance. Regular inspection and cleaning prevent buildup and wear, ensuring the dies retain their high precision and long service life.

Q: What benefits do heat-treated and polished surfaces provide for the cutting dies?

A: Heat-treated and polished surfaces enhance the dies resistance to wear, corrosion, and high temperatures (up to 250C), ensuring reliable operation and minimizing downtime in high-volume packaging environments.

Q: When should these dies be replaced or serviced in high-volume production?

A: Duplex Box Cutting Dies are engineered for over 100,000 cycles. Regular checks for wear or tolerance deviation are recommended, and servicing should be performed at any sign of performance reduction to maintain cutting accuracy.

Q: Where are these Duplex Box Cutting Dies commonly used?

A: These dies are primarily utilized in the packaging industry across India, particularly for duplex box making where high precision and efficiency are critical in large-scale manufacturing.

Q: How does the customized design process work for unique box specifications?

A: Manufacturers can provide detailed box specifications, upon which the dies are custom-designed using advanced CNC and EDM processes to ensure precise fit and function, accommodating varied production needs.

Q: What materials are used in the construction of these dies and why?

A: The dies use high-strength alloy steel, carbide inserts, and wear-resistant steel to maximize hardness (56-58 HRC), durability, and edge retention, meeting the demands of precision and extended cycles in industrial packaging.

Q: What is the primary advantage of the male-female die assembly in duplex box cutting?

A: The male-female die assembly ensures clean, accurate cuts by providing precise alignment and support during operation, reducing material waste and enhancing the finished quality of duplex boxes.